.jpg)

Plating factory is located in Yueqing plating environmental protection industry park, covers an area of 6.5 mu, building area of 7000 square meters, owns the plating line more than 20, 1 Dr. ,undergraduate technical personnel 5, more than 120 employees. Our goal is to become gold plating leader in electronic plating industry.

.jpg)

.jpg)

.jpg)

In order to ensure the product process control and performance testing, we invested a lot of testing instruments.

X-ray plating thickness instrument

Fischer X-ray Duv is the world's most advanced thickness instrument currently, can accurately measure gold thickness below 1 u . Result approaches to authority FIB test result.

.jpg)

.jpg)

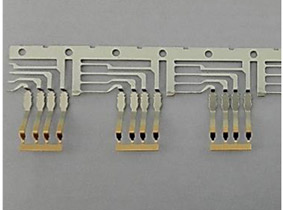

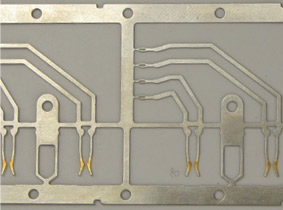

With 4 continuous production line( 1 machine 2 lines), can do gold plating, Palladium nickel alloy, nickel phosphorus alloy, immersion tin plating for plane or special terminal by spot, immerse, brush plating. Every day can stably produce Fu "- 50 u" precious metals products.

.jpg)

.jpg)

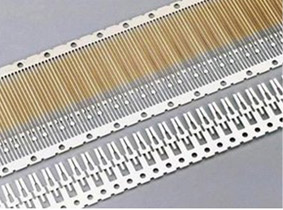

Also known as gold round pin, it is mainly used for bonding, network connectors

Gold wire plating production line: 10 (3 thick gold, 7 thin gold)

Standard production capacity: it can produce 1.7 T/day

Plating specification: Fu"-50u"

We use high-end technology, with low internal stress for thick gold wire above 15u" , no crack after moulding. Salt spray effect is stable. Salt spray test can withstand more than 24h for final product Fu "- 6 u", more than 48h for 15 u" - 50 u".

The country's first palladium gold plating production line and acquire domestic patent. Patent no. 201110252224.8

.jpg)

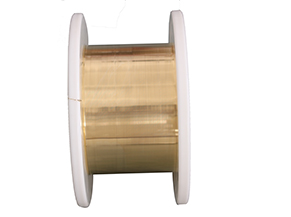

Copper strip used for: shielding connectors.

Copper strip plating line: 1 production line(1 machine 2 lines). Standard production capacity is 5 t/day, can produce maximum width of 200 mm.

Our characteristics: appearance bright and weldability.

Roll barrel plating production line: can do Fu”-70u”hard/soft gold, palladium, palladium nickel, bright /fog tin, high temperature tin, bright nickel roll barrel plating and hanging plating for bulk product.

Expertise in deep hole plating processing